Unclaimed: Are are working at Autodesk Fusion 360 ?

Autodesk Fusion 360 Reviews & Product Details

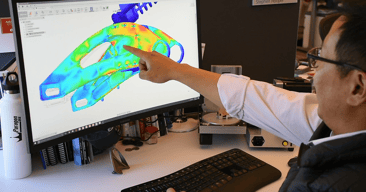

Fusion 360 is a professional cloud-based 3D CAD program that lets users design and manufacture products using CAD, CAM, and PCB software. The feature-rich 3D printing software offers tools that include simulation, assemblies, 3D printing, generative design, tools sculpting, and CAM. That platform is known for having numerous product design options and cross-cloud capabilities, making it perfect for remote team collaboration, especially for large-scale projects.

| Capabilities |

AI

API

|

|---|---|

| Segment |

Small Business

Mid Market

Enterprise

|

| Deployment | Cloud / SaaS / Web-Based, Desktop Mac, Desktop Windows |

| Support | 24/7 (Live rep), Chat, Email/Help Desk, FAQs/Forum, Knowledge Base, Phone Support |

| Training | Documentation |

| Languages | English |

-The cloud based system is great for collaborating with remote team members -The system is fairly customizable -The Upchain team has been helpful training our team and providing help when we run into issues

-There is huge potential in the features to share files with vendors. I would like to see this expanded to include neutral file formats and customizable file naming -I believe the CAD plugin can be improved for speed of use with features like an automatically expanding tree -I would like additional control over the revision system

We are designing mobility products in Upchain. We recently have had to move to the entire team working remotely. Upchain has allowed us to do this smoothly.

1. UpChain provided a great opportunity that for the whole team (not only inside the company, also combined with external vendors and clients) to be able to work on the same platform, from pre-prject til the end of R&D process. 2. UpChain create a bridge to link CAD users (MD, ID, ED) and non-CAD users together, so we don't need to rely on a installed CAD software for everyone. Everyone can check the CAD file easily. 3. The issue ticket system is amazing. Once a issue is found, now we can quickly create a ticket and assign it to the people who will take charge of fix it. It also create a link that everybody will know who gona take the responsibility and who gona review and approve it. 4. Compare to Solidworks EPDM, Upchain doesn't require a server setup. So everybody can access it from anywhere. Doesn't need a VPN.

1. Upchain has a plugin for Solidworks. As a CAD worker, I would like keep all features in the plugin, so I don't need switch to browser to make some operation. But in current Solidworks plugin version, some features are still only available in browser. 2. CAD file version management for Solidworks plugin still need more work to make it more practical to check/compare different versions. 3. In the support section, most of the Q&A are based on browser version. Hope we can have more Q&A focus on CAD software users.

1. When working remotely, no VPN needed. 2. Quickly check CAD and compare different versions in browser.

It is User friendly and Good customization as per users requirements

Not as such any. All is good. Except instead of Project I think there Should be folders and where we keep respective info.

Yet I didn't have any exp or problem with upchain.

Great way to store data and files in searchable locations. I really enjoy the project management features built in to the system. Customer service is very good at supporting users.

There were a few minor bugs that had to be worked out initially that made the user experience slightly not ideal. These have been worked out now.

Keeping projects organized, controlled, and searchable

Upchain have kept open and frank communication during the entire process, answering any and all questions we had as best they could. When we asked some difficult questions, the CEO and CTO were more than happy to jump in to help clarify, really exceptional customer service.

I am yet to begin using upchain in a production environment. However the only thing I've seen so far that it can't do out of the box is serialise file naming of CAD parts.

upchain will bring structure to our design process, and ensure that products and designs consistently improve. It will also cut down on rework, and duplication of work.

A software that allows you to work together with a team or individually if you wish and is a very powerful tool

WHen an update is made it must be re-installed again

The collaboration between teams and to impove the production in a project

The ability to collaborate and ensure everyone is working off the most up to date revision. Previously we found ourselves working on multiple copies of the same part and never being sure which should be used in production.

Frequent updates requiring re-installation

We no longer have time wasted on figuring out what files are production, r&d, and testing

the user friendly Interface is great! it is very easy to use

the licensing structure of the system is not shared so it can be very expensive if you have more than 300 employees

Great Change Control and Audit tracking for FDA and ISO Audits

The Autodesk Fusion Lifecycle PLM system has been a welcomed addition to our process. The hosted software requires no hardware or software installs and is a breeze to get up and running with. The service seems to be rock solid (based on AWS) and we've had no trouble with downtime or lagging. The suite of tools for mobile devices coupled with the web interface means we always have access to our data, regardless of where we go and what we do.

The building of all of the rules is a serious trip. It will take you quite some time to get them built correctly and many of the various menus are not co-located within the same area of the admin tools. While every PLM software takes time to get the roles/responsibilities and rules sorted, it was painful to have to navigate between menus buried several screens apart to verify functions, check spelling, etc.

Fusion Lifecycle has enabled us to keep our engineering process streamlined and connected. With the email and mobile based tools we are able to keep up with design change tasks and reviews across our organization, regardless of who might be out of the loop at the time. We have saved months of development time by automating design checkoffs with our customers and strategic partners. We're also able to track equipment maintenance and process failures for analysis of our entire manufacturing chain from design through customer returns.

Provides a lot of improvements over previous versions. Allows the user to take control over their work with the help of the software. All data is available for the user immediately. Automates important jobs and small to-do items which helps with better maintenance of people, project and the workforce. Allows version control features by keeping log of changes.

Does not deliver the perfect solution to replace other products and PLM alternatives.

It helps me organize all spreadsheets, docs, powerpoints in one place. Provides many configurations for the user to take advantage of. Cost and Quality update and management are important features covered.