Unclaimed: Are are working at Autodesk Fusion 360 ?

Autodesk Fusion 360 Reviews & Product Details

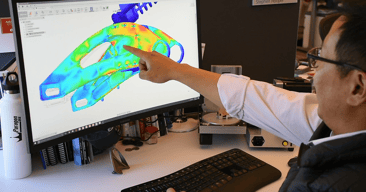

Fusion 360 is a professional cloud-based 3D CAD program that lets users design and manufacture products using CAD, CAM, and PCB software. The feature-rich 3D printing software offers tools that include simulation, assemblies, 3D printing, generative design, tools sculpting, and CAM. That platform is known for having numerous product design options and cross-cloud capabilities, making it perfect for remote team collaboration, especially for large-scale projects.

| Capabilities |

AI

API

|

|---|---|

| Segment |

Small Business

Mid Market

Enterprise

|

| Deployment | Cloud / SaaS / Web-Based, Desktop Mac, Desktop Windows |

| Support | 24/7 (Live rep), Chat, Email/Help Desk, FAQs/Forum, Knowledge Base, Phone Support |

| Training | Documentation |

| Languages | English |

Upchain provides a great service for BOM and change management. The online viewer for browsing 3D models imported from our Solidworks developers is great for non-Solidworks users (quality team, management team, electrical/software developers, etc.), and even for Solidworks developers that aren't on their CAD computers. The price point for Upchain is also really great and hard to beat for small teams. The customization of workflows is really nice as it allows our company to start making different paths for different products/stages of the design.

User interface could be tweaked for repetitive tasks, like making changes to a part in the expanded BOM, but then the BOM collapses after the change takes effect you must re-expand all levels. Also, document management that matches part management would be excellent. The ECR/ECO/ECN process could be tailored more closely to ECO processes like ISO 13485, especially with the ECN aspect which doesn't really match the typical "notification" stage that we are working with in the medical space. The ability to customize the part's metadata further, and remove fields that aren't used even if they are defaults in the system. This would be nice to make it cleaner and less cumbersome when reviewing.

We were managing BOMs and parts using Excel, and now using Upchain which is great for that. We were also doing our own "vault" for solid works parts, which is now being done by Upchain and helps with collaboration.

Easy to use and understand without help. Very useful for managing CAD models and drawings. Very easy to perform engineering change along with tracing the changes completed previously.

Not able to create new part number for small change (design shared with other assembly with small change) in current assembly and need to restart from zero.

Managing CAD models and drawings. Creating bill of material for manufacturing drawings for vendors, Bill of Materials for purchase and assembly team. Mostly importantly easily able to create Bill of materials for different products.

I like that it combines all the documents needed in one place. It is easy to view everything at a one stop location. I also like that it is Cloud based and can be accessed by multiple users at the same time. This is really beneficial especially that we have couple team members in different remote locations, and can't have access to the local server. I also like the user friendliness of the file. It is not too complicated, not so many buttons are present that could mess things up.

It can include more things and more capabilities. I think some points to improve is having the ability to manage more documents such as FMEA & APQP as well as work instructions documents. This would be super beneficial! One thing I dislike, is the duplication of some documents. I wish there is a feature to lock things and control them better. This would be super beneficial from a document control perspective. We wouldn't want two documents to be copied twice and worked on twice. I also suggest having approvals of parts or drawings so it can be controled more.

We are trying to have all our files in one system in relation to a part number. Upchain have helped managing them and grouping them in one place. It is easier to use this tool as a one-stop for everything related to a certain part.

What I like most about Upchain is how it keeps the guesswork out of knowing where we are with a product launch. We've set up workflows so that our entire team can be on the same page as to where we are in the launch cycle.

So far, there is nothing I've come to dislike about Upchain. It's easy to use, I've been properly trained, and our organization is beginning to implement the usage across multi levels of our business.

By using Upchain, I know longer question if I am looking at the most current revision of a BOM or material. Before we were always left wondering because the information wasn't kept in a central place.

It is one of the only cloud based PDM/PLM solutions available at a reasonable cost. Other software only offers PLM, no CAD storage and a significant set-up fee.

Need some more BOM functions such as being able to re-arrange the position of a part within the BOM. We also need to figure out how to integrate with our apparel design team who uses a lot of 2D and Adobe software.

We are improving communication with our supplier development, purchasing, engineering and quality teams. We have seen tremendous improvements in change management and maintaining project design freeze. We have reduced confusion about product specifications be being able to directly link documents and drawings to the part. Product cost is also finally becoming transparent across the organization.

-It keeps work flow very smoothly. This tool has the ability to allow multiple users to work together on the same project. As Engineers we are able to work together as a team through Upchain. -It also has a wonderful features for management of projects. -It integrate with other apps like Microsoft Office, etc. -They also have a very reliable customer support team to help their clients. -Tracking and monitoring of projects progress. -Very customization tool to fit any business styles. -Files and documents storage, whereby the user can access the stored file in a very easy way.

Upchain works everything out well and its a very useful tool in many businesses. Only that the its updates happens in re-installation process.

-Managements of our Engineering files and other documents. -Enabling of team work flow. -Time saving and others.

Cloud based, very powerful, plug-ins for Solidworks, Office, and Visio are great. Assistance from customer support is excellent.

With a lot of power comes complexity, but once you work through the steps it make sense.

Document / version control, CAD model storage.

Advanced plugins for NX, Creo, Catia, Inventor, Solid Edge, and SolidWorks. This allowed our engineers to integrate with our systems for a streamlined process.

Learning curve is average for this type of product.

Provide CAD Reading tool for our engineers.

I love how automated I am able to make simple jobs and even complicated ones.

There are a few bugs that make it sometimes difficult to work with.

Tracking of Engineering changes.

The ability to customize the software to our workflow that we need to fit our company path. The fact that we can create a similar look for completely different workflows is a blessing as well for smother transition from task to task.

If we do not tweak the layout often, sometimes it takes a bit of working with it to get the groove back. Like riding a bike, but a little longer re-learning curve.

We are using it for Internal process tracking, things like software updating, miles traveled reporting and other Internal tracking needs, expanding uses to include as many workflows as we can.